Reliability Training Courses

High Quality Mentoring and Training Courses

Spartakus Technologies provides top-notch training to elevate your learning journey from a beginner to an expert level. Whether you're just starting out, are aiming to bridge knowledge gaps, or are ready to further advance your skills, we are here to empower you with the necessary expertise and proficiency to successfully implement and lead reliability initiatives at your site.

INSTRUCTOR

Yoann Urruty10 years training experience

Over 1,000 experts trained

Co-creator of Spartakus APM

CMRP Senior Reliability Engineer

I greatly appreciated the webinar. It allowed me to change my perception, and now I believe in it 100%.

Trusted by our customers

Our most popular training:

Maintenance Strategy Optimization Workshop

In this workshop, we will learn how maintenance teams can define the right task to be done at the right time, the right way by the right person.

We will alternate theoretical content with a practical exercise in a dedicated software for a conveyor that has poor maintenance strategies.

At our partner office

At your location

Objective

Review the Maintenance Strategies definition process to increase the reliability of your equipment and lighten your work management daily.

Target Audience

Maintenance supervisors, reliability engineers and specialists, plant managers.

Duration

2 - 3 days

-35%

Machine downtime

+65%

Equipment coverage

> $100k

Total savings

Syllabus

- Background

- Preventive maintenance and its challenges

- Preparation for the exercise

- Visit, photo taking of targeted equipment

- Decomposition of equipment

- The challenge of failure modes

- What to do with existing preventive tasks?

- Eliminate existing tasks

- Optimization of remaining tasks

- Further optimization of remaining tasks

- Risk analysis of uncovered failure modes

- Adding tasks

- Final validation of the maintenance plan

- Process performance indicators

- Creation of maintenance routes

- Successes/failures and advice

I really enjoyed the workshop. I learned to anticipate problems before they arose, which revolutionized our approachMaintenance Planner

CMRP Training and Workshop

This 4-day training covers the breadth of knowledge in maintenance and reliability as defined by the SMRP (Society for Maintenance and Reliability Professionals) and offers a good balance between theoretical courses and practical workshops.

At our partner office

At your location

Objective

The participant will gain an in-depth understanding of reliability and maintenance management, as well as asset performance. They will also learn how best practices can be applied. The participant will be able to compare his skills with world class standards.

Target Audience

Engineers, technicians, reliability specialists, supervisors, planners, maintenance managers, production managers, plant managers

Duration

4 days

CMRP

Accelerated preparation

Syllabus

- Creation and implementation of an efficient strategic plan & performance measurement

- Environmental and safety risk management

- Communication with different actors

- Change management of processes and equipment, in accordance with laws and world class standards

- Development of the organizational structure

- Work identification, validation and approval

- Prioritization, planning, scheduling and execution of work

- Establish a reliability plan for new and existing equipment with cost justification

- Documentation, analysis, follow-up of the work and performance measurement

- Effective use of information technologies

The training opened my eyes to the importance of reliability in all areas. Every lesson was a step closer to operational excellence and peace of mind.Maintenance Engineer

Work Management Simulation

Through the game, the participants are led to understand how each employee in an organization has a role to play in the path to reliability.

At our partner office

At your location

Objective

The participant will be able to understand and apply the reliability process in his or her work environment. The participant will learn to organize and assemble a strategy that takes any program to the next level.

Target Audience

The Reliability Simulator is an awareness activity that affects everyone involved in maintenance and leads to a new vision and willingness to change for the better.

Duration

1 day

-80%

Reactive maintenance

+100%

Equipment history

+100%

Inventory control

Syllabus

- Simulation of a real maintenance process

- Establishing a planning organization

- Applying LEAN to everyday maintenance

- The impact of a support system on job productivity

- Measuring and capturing business productivity

- Daily planning and weekly dispatch

- Defining Planning Gaps: Comparison of Planned vs. Actual Outages

- Work Prioritization: Overview

- The impact of reactive maintenance on planning & scheduling

- Developing an effective information history

- Developing a work management strategy

I always thought maintenance was reactive, but this training has shown me how to be proactive. I now have the tools to create an environment where equipment runs smoothlyInventory Assistant

Executive Training - Reliability Workshop

At the end of the workshop, the participants will have a good understanding of the current state of the plant reliability processes currently being deployed at the site.

They will understand the gap between the current state of the plant and optimal state, connected to a benefit analysis, to prioritize an action plan and close the gap.

At our partner office

At your location

Objective

The participant will gain the understanding of the necessary elements that need to be put in place to have a reliable and sustainable plant.

Target Audience

Industrial plant executives, industrial plant managers, operation managers, maintenance managers, reliability specialists

Duration

1 - 2 days

The training made the link between data and decisions. I have acquired the skills to analyze maintenance data and make informed decisions to improve the efficiency of my plant.Plant Manager

Reliability

Accelerated knowledge

Syllabus

- Reliability for industrial production

- The impact of reliability on the financial results, on safety and sustainability

- What are the 7 elements that all reliable plants have in common

- Business case for reliability, what is the opportunity for your specific plant

- Process that needs to be implemented and synergies that are essential for success

- Leading and lagging key performance indicators

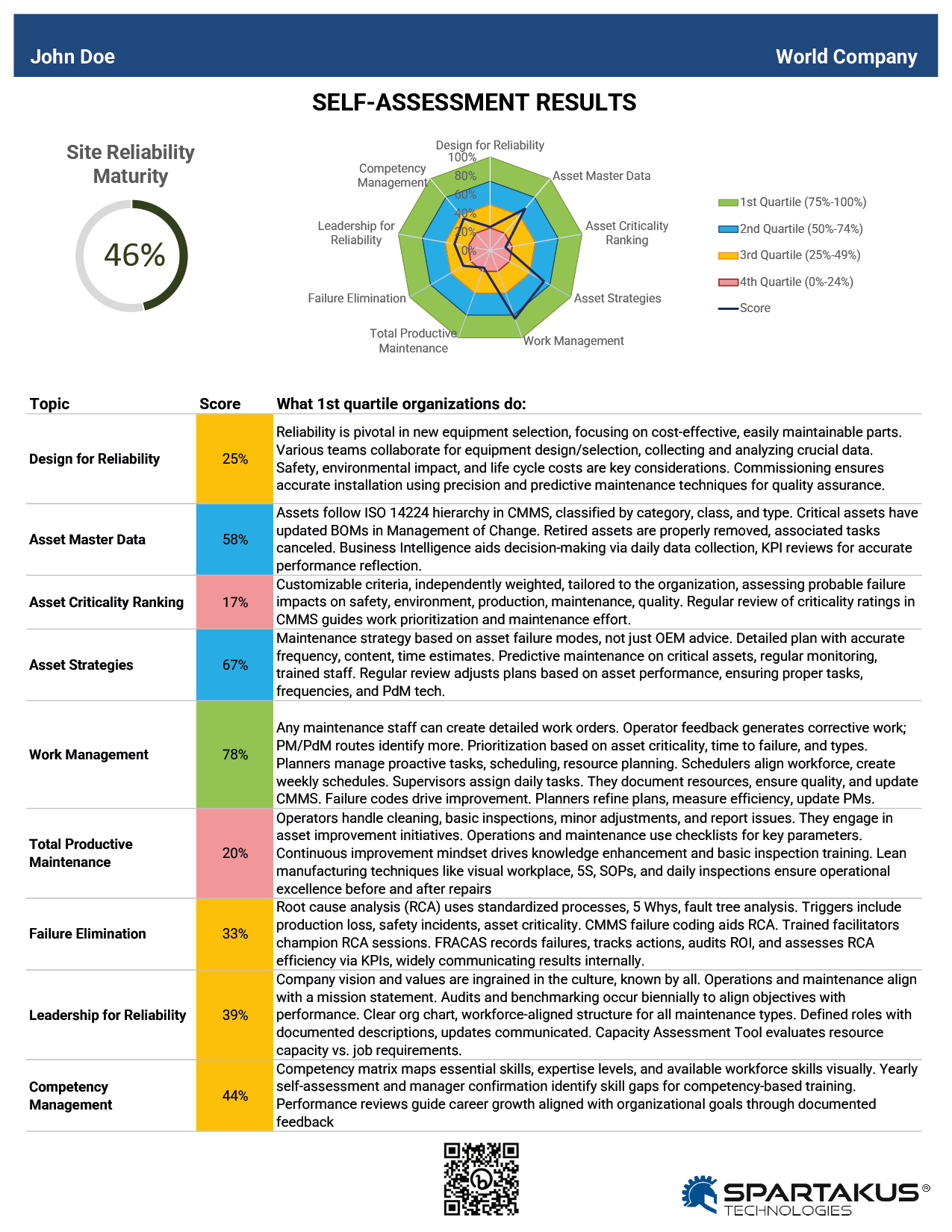

- Reliability assessment workshop

- Self-assessment of the reliability maturity at the plant

- Gap analysis and prioritization of a possible action plan

Example of an end-of-course report

Spartakus Technologies offers comprehensive training for all skill levels, from beginners to experts, in the field of reliability engineering. Our mission is to empower individuals with the knowledge and proficiency needed to implement and lead reliability initiatives effectively. We provide foundational training for beginners, advanced courses for those looking to bridge knowledge gaps or enhance their skills, and ensure our content remains up-to-date with industry advancements. With Spartakus, you can confidently take charge of reliability initiatives at your site, driving efficiency and success.

CMRP WORKSHOP

CMRP WORKSHOP