Pricing Strategies and Techniques

How much does the Spartakus APM software cost?

Spartakus APM (Asset Performance Management) operates as a Software as a Service (SaaS) solution. The pricing for this platform is subject to variation based on several key factors. Among these factors, the following have the most significant impact on the pricing:

- The number of assets.

- The extent of technology deployment within the platform.

- Integration with other platforms, including CMMS (Computerized Maintenance Management Systems), Historian systems, and Oil Labs.

- The number of offline mobile application access licenses required.

Once the platform is fully implemented, the recurring monthly costs can range from $800 to $2,000 per month.

How much does the implementation of Spartakus APM software cost?

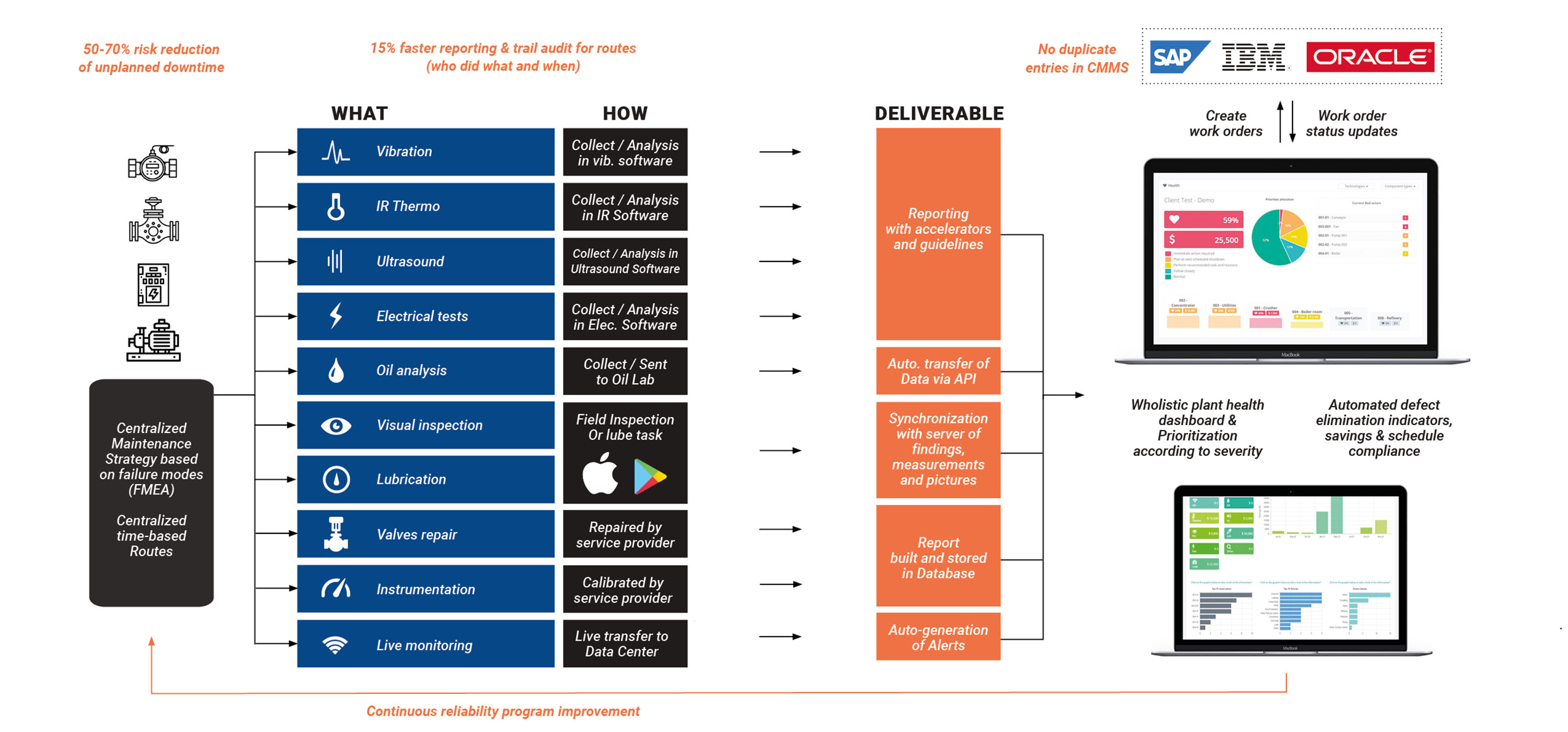

The cost of implementing Spartakus depends on various factors such as the type of technology being deployed, number of technologies and the quality of the data that needs to be input to the platform. To provide a more comprehensive understanding of the pricing structure, we have categorized it into distinct technology segments: PdM routes, PM routes, live monitoring, and third-party connectivity.

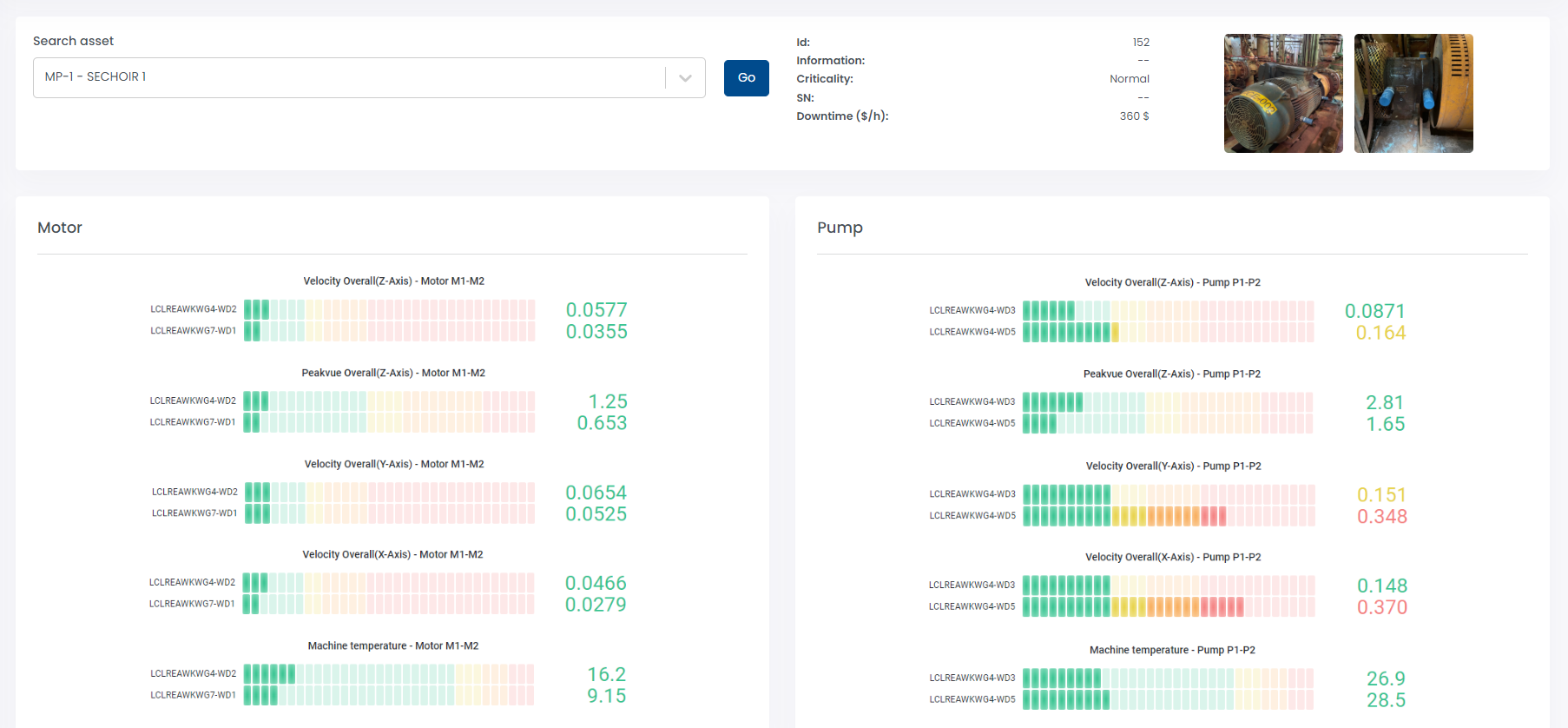

PDM Routes

When discussing Predictive Maintenance (PdM) technology, the most frequently incorporated PdM technologies within our software encompass vibration routes, infra-red thermographic routes (both mechanical and electrical), and mechanical ultrasonic routes. When it comes to integrating PdM into Spartakus, it stands out as the simplest and most direct technology to implement, and here's why. Most of the tasks included within each route are fairly similar one to another (Ex: Perform a vibration analysis using the vibration collector), therefore the implementation time is fairly fast and cost-effective. For each PdM technology, we estimate approximately 60 hours of work, covering all required tasks for a successful implementation such as data manipulation, standardization, formatting, uploading, data validation, training, and continuous support. This translates to an estimated cost ranging from $7,000 to $10,000 per technology. However, it's important to note that despite the straightforward nature of this implementation, pricing can be influenced by factors such as the number of components, number of tasks, and the quality of the existing documentation.

PM Routes

When discussing Preventive Maintenance (PM) implementation within Spartakus, we are referring to visual inspection, operator rounds and lubrication routes. When it comes to those projects, a lot of factors will come into play to define the pricing, such as the number of tasks and your existing content.

It's essential to keep in mind that our primary goal is to ensure the integration of value-added and objective tasks into Spartakus. This involves incorporating as many details, measurements, data and procedures as possible to enhance the robustness of your program.

For instance, in the context of a lubrication program, we strongly recommend comprehensive inclusion of critical details such as the necessary type of grease, the quantity required, the frequency of greasing, and the appropriate greasing procedure when undertaking a Spartakus implementation. The same thinking is applied for operator and visual inspection rounds, we highly recommend we implement objectives tasks with specific measurements with min/max/target to ensure that the results of your PM program are as little impacted as possible by the person who will do the task, ultimately striving to make it foolproof.

It's worth noting that if you already possess all this essential information, the implementation process is likely to proceed smoothly and efficiently. On the other hand, if you do not already have that level of details for your PM and lubrication program, our team of technical experts can support. They can guide you in the data collection process or even handle the entire task creation process on your behalf. Consequently, the duration and cost of a PM implementation program can vary significantly, spanning anywhere from 100 to 400 hours of work, equating to a cost range of $15,000 to $50,000 or more. The price will depend on your current data, numbers of components included in the program and the implication of our technical experts.

Live monitoring

Regarding Live monitoring, several factors influence the project's cost, including the number of assets involved, the type of data integration required, the necessity of analysis services, and the existence of pre-established connectivity.

Third-Party connectivity

Our most prevalent forms of third-party connectivity encompass oil analysis conducted by external laboratories and CMMS (Computerized Maintenance Management Systems). Here's what influences the pricing for each of these categories:

Oil analysis

The cost of connecting to oil labs is primarily influenced by two key factors: the number of components you intend to link to Spartakus and if an API connection already exists for your oil lab. When we mention the "number of components," we are referring to the total count of components on which oil analysis is performed, rather than the number of individual oil samples. For example, if we conduct oil sampling on a gearbox every month, it counts as a single component, not 12 separate oil samples.

The essential step involves mapping your oil analysis lab to Spartakus APM, which typically takes around 5 to 10 minutes per component. It's important to note that this mapping process is a one-time effort and is not a recurring cost.

Another critical determinant of pricing is whether an existing connection with your oil lab is already in place. If a connection is pre-established, accessing this connector may incur a fee, typically ranging from $1,000 to $2,000 yearly. Conversely, if no connector currently exists, we will need to create one, which usually involves a cost ranging from $5,000 to $7,000.

As of now, we maintain connections with various oil labs, including Fuildlife, MyLab, ALS, SGS, Polaris Lab, Oilview, LTI, Oleum, with Wearcheck incoming. Overall, the cost for oil lab connectivity can vary between $3,000 and $8,000, depending on the factors mentioned above.

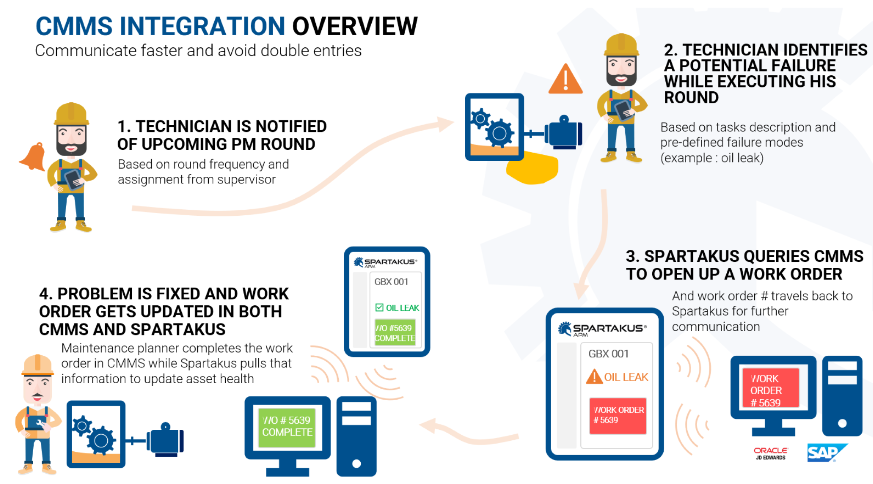

CMMS

When it comes to CMMS, we are aware that this can be a very sensitive subject for your business for connectivity and that we must provide the most cybersecure connector possible. That being said, we are partnered with a third-party that a certified connector that will respect the best-in-class cybersecurity requirements. The price for the connector depends on the CMMS and the number of assets needed to be linked with Spartakus. All and all, the range for a CMMS connectivity can go from 20k to 50k for the first year doing the implementation, and then 5 to 10k for the recurring maintenance cost of the connector.

Other technologies and third-party connectivity

Please be aware that Spartakus can incorporate various technologies beyond the one mentioned earlier, either via route-based technology or third-party system integrations. In the "others" category, our most frequent projects include integrating third-party systems like historians (e.g., Pi) and analytical systems (e.g., Power BI). As for route implementation within this category, we often handle NDT testing, electrical testing, and calibration.

Note that pricing details have not been included for these categories as they are less commonly encountered projects. Instead, they are typically handled on a case-by-case basis, customized to meet the specific needs and circumstances of each customer. However, like most other categories, these projects will be strongly influenced by factors such as the number of components involved, the existence of pre-existing connectors, and the type of data that needs to be imported or exported.

Implementation cost by technology

| CATEGORY | TECHNOLOGIES | COST RANGE ($) | COST TYPE | FACTORS THAT INFLUENCE COST |

|---|---|---|---|---|

| PDM routes | Vibration | 7k - 10k | One-time | - Number of components - Number of tasks - Quality of existing documentation |

| Infrared Thermography (mechanical & electrical) | ||||

| Ultrasonic (mechanical & air leaks) | ||||

| PM routes | Visual inspections | 15k - 50k | One-time | - Number of components - Number of tasks - Quality of existing PM program - Spartakus involvement in reworking/optimizing existing PM program |

| Live monitoring | Vibration | 3k - 20k | Yearly | - Number of components - Number of tasks - Type of data to bring over - Does a connector already exist? - Involvement of Spartakus for analysis & diagnosis |

| 3rd party connectivity | Oil analysis | 3k - 8k | One-time | - Number of components - Does a connector already exist? |

| 2k | Yearly | |||

| CMMS | 20k - 50k | One-time | - Number of components - Does a connector already exist? - Type of data to bring over |

|

| 5k - 10k | Yearly | |||

| Others | Others (Historian, Power BI, NDT Testing, Electrical testing, calibration, etc.) | TBD | One-time | - Number of components - Does a connector already exist? - Type of data to bring over/export |

| TBD | Yearly |

Discover the cost of implementing an Asset Performance Management (APM) software. Learn how factors like technology type, data quality, and integration impact pricing. Get insights on PdM, PM, live monitoring, and third-party connectivity costs. Find out about APM's pricing structure, including factors like assets, technology deployment, integration, and mobile access licenses.