Reliability Consulting

High quality services by and for reliability profesionnals

By conducting a thorough assessment of existing processes, our experts can highlight areas that need attention and suggest ways to optimize operations, reduce costs and improve productivity. They can also identify opportunities to implement new technologies or techniques that can provide a competitive advantage.

Overall, our reliability experts will be able to help your company stay ahead of the curve by providing valuable information and recommendations that can be used to make informed decisions and continuously improve operations.

Our support has, on average, achieved the following improvements:

Reduction in failure risks

Reduction in maintenance time

Increase in machine availability

Increase in planners' productivity

Months for average ROI

Trusted by our customers

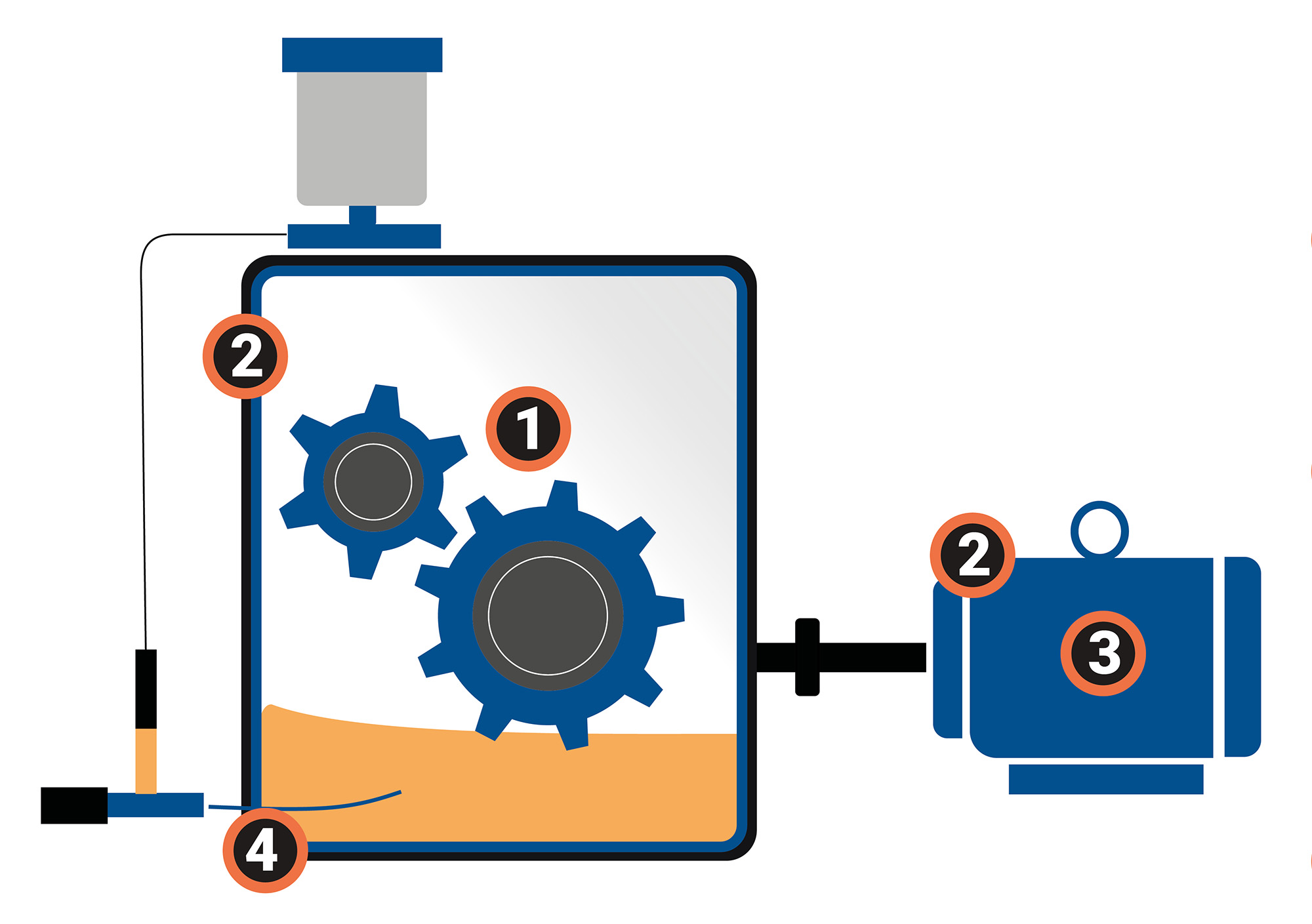

MAINTENANCE STRATEGIES OPTIMIZATION

From subjective to efficient and risk-based inspections

Get rid of preventive maintenance tasks such as «Check motor» or «Check pump» ! Our failure-modes based optimization process quickly highlights the gaps in all preventive maintenance programs.

VISUAL INSPECTIONS - 7 days - Operator - RUNNING

Visually inspect for leaks and breather saturation.

Failure modes covered : Leaking, Noisy, Lack of oil, Saturated breather.

VIBRATION ANALYSIS - 30 days - Vib. tech. - RUNNING

Failure modes covered : vibration.

GREASING - 90 days - Oiler - RUNNING

Lubricate the bearing with an ultrasonic device.

(DE: 3 grams, NDE: 6 grams. Type: Unirex EP 2).

Failure modes covered : lack of lubricant.

OIL ANALYSIS - 90 days - Oiler - RUNNING

Take an oil sample and send it to lab for analysis.

Failure modes covered : Contamination, Degraded oil, wear.

Business Case

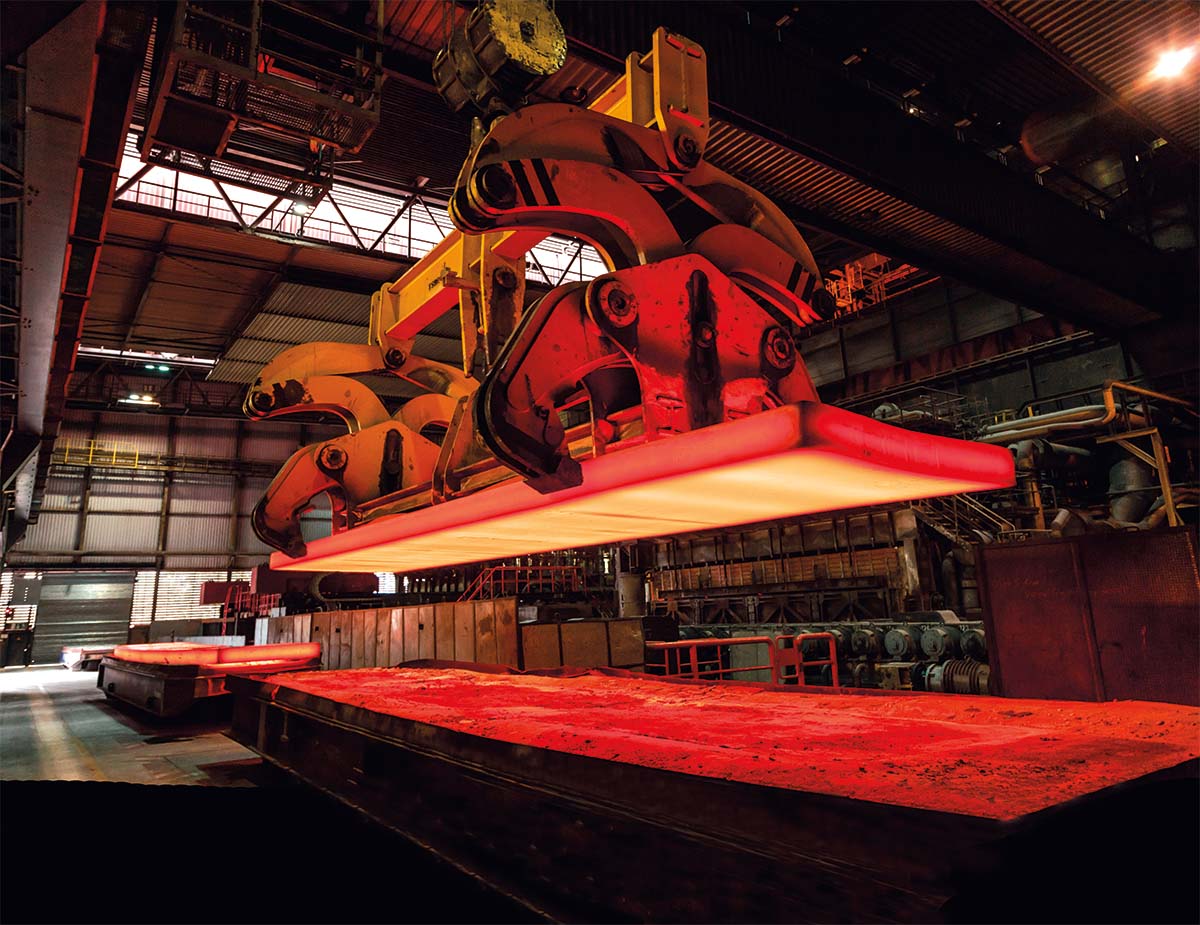

Our client, a major steel factory, had to reduce financial losses from assets’ mechanical failures. It was therefore imperative to establish a culture of reliability and proactive asset management.

1. FIELD DATA COLLECTION:

Our experts spent time in the field collecting data from the machines (pictures, drawings, existing

maintenance tasks, history of failure) and preparing our optimization tool.

PM Optimization activities were held based on failure modes to allocate the right tasks to the right people at the right time. Final new maintenance strategy was validated by millwrights and technicians on the field. 3. IMPLEMENTATION OF NEW PROGRAM:

Technicians and engineers deployed Spartakus APM to execute the new PM tasks on 16 highly critical pieces of equipment. On the first iteration, many issues were identified and corrected on the go to prevent upcoming catastrophic failures.

They are a good partner who is always ready to support us and bring new solutions thanks to a competent team.Senior Maintenance Manager

$1.2M

Documented Savings

+100h

Annual Production

-1 Month

Spartakus APM Deployment

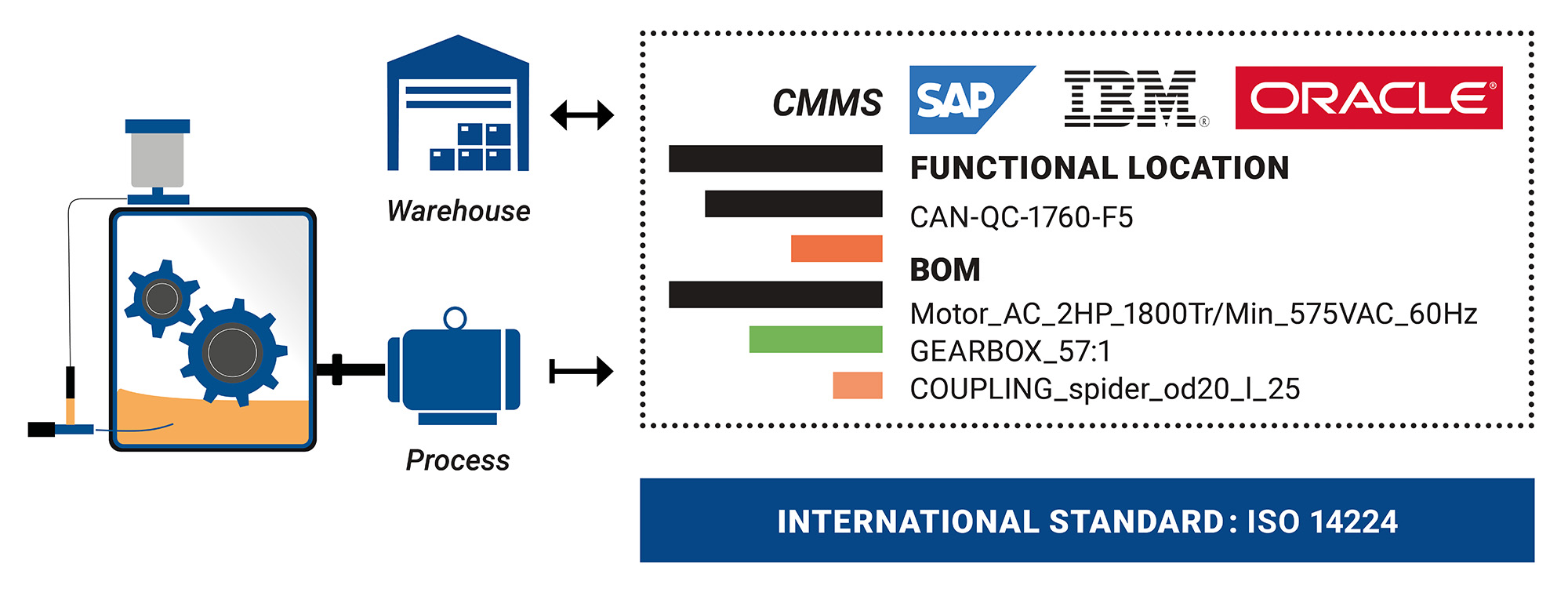

ASSET MASTER DATA

The foundation of every maintenance program !

Having completed a Master Data initiative in many plant sites, the result is that:

- Hierarchy (MEL) is : detailed, accurate and complete

- Parts (items, materials) are : detailed, unique, easily ordered, optimally stocked

- Parts lists (BOM) are : accurate and complete

Business Case

Our customer, a major player in the pulp & paper industry, was setting up a greenfield plant site aiming to be a benchmark in the organization. For that reason, asset master data needed to be done perfectly from the get-go.

1. STRATEGY SESSION AND STANDARD DEFINITION:

Based on ISO14224, the rules to be applied for the project length were defined : differences between assets and parts?

How should asset numbers and descriptions be developed? Etc.

A complete and detailed asset hierarchy, as well as all the necessary parts and bill of material (BOM) were developed. Also, parts were consolidated with the existing catalog which resulted in significant deduplication before startup. 3. IMPACT:

Positive effects on work management, inventory practices, continuous improvement process and safety at the plant.

Spartakus has helped us revolutionize our approach to asset master data, improving our operational efficiency and opening up new opportunities for our company.Senior Reliability Manager

$7.6M

Return of Investment

-20%

Unplanned Downtime

>$2M

Not acquired duplicated inventory

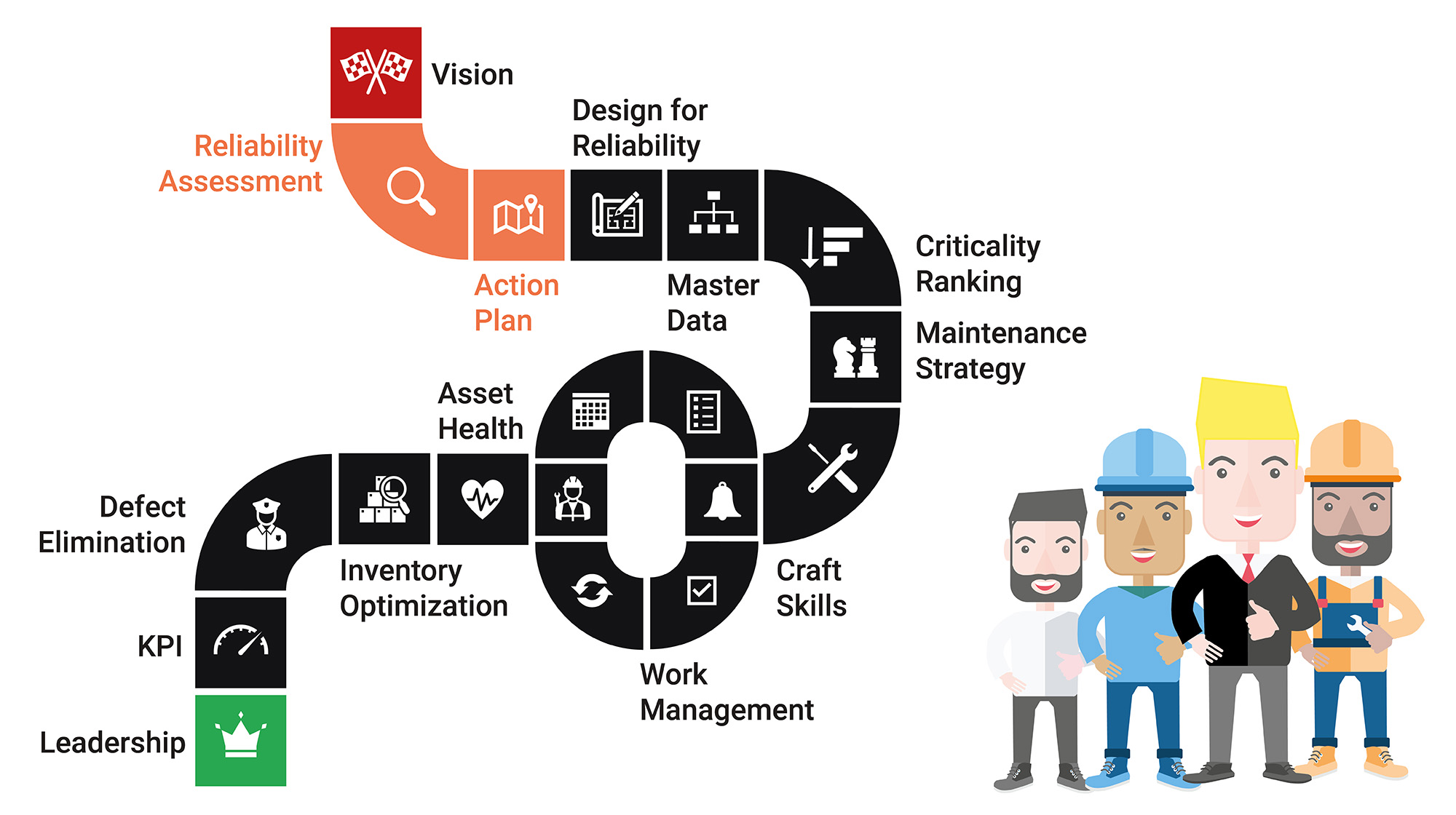

RELIABILITY DIAGNOSTIC

On the road to excellence !

Spartakus Technologies’ diagnostic and action plan proposal can help achieve better competitivity, profitability, safer work environment and sustainability goals, based on industry best practices.

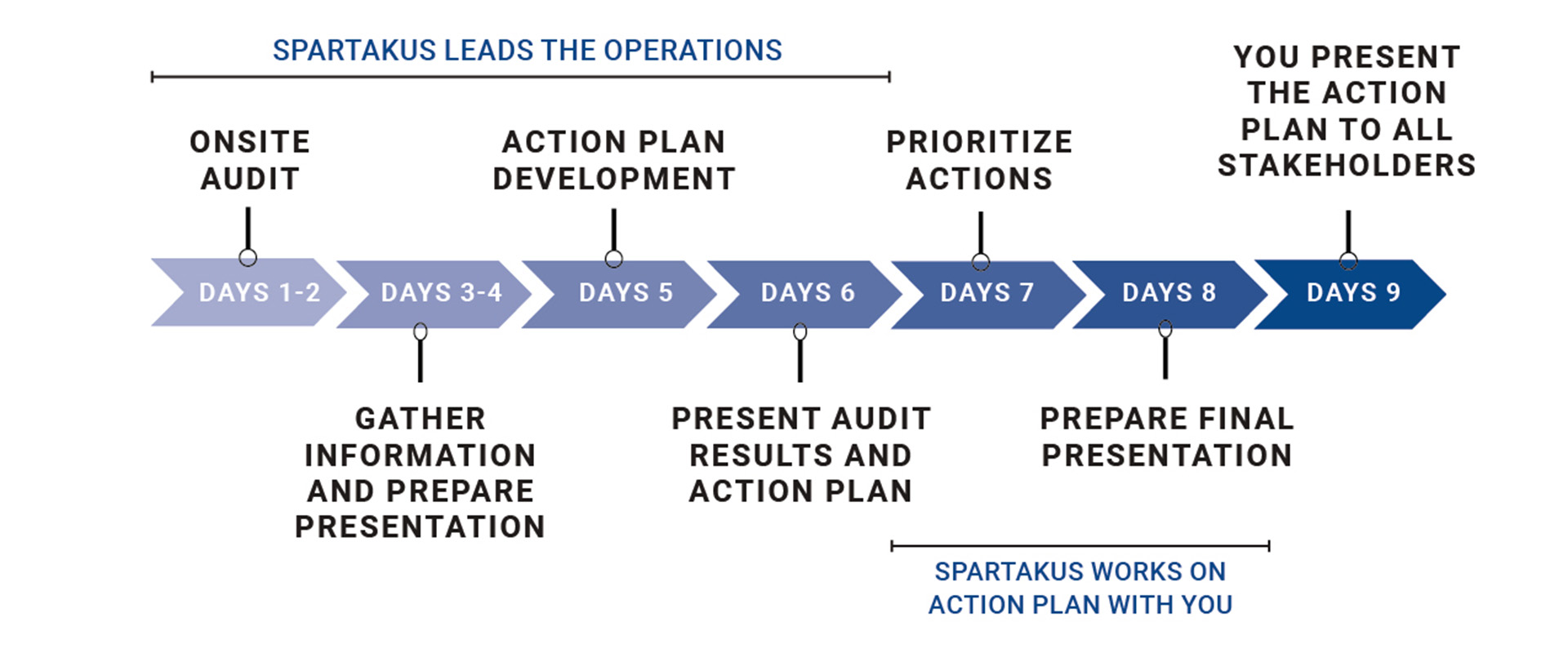

Description

Prioritize and estimate the associated costs of the action plan.

Evaluate potential benefits after action plan is in place.

Maturity evolution and project management through cloud platform.

The process carried out with your teams has been efficient and has added great value to our operations. Major thanks to the team !Plant Director

Our reliability experts can help your company optimize operations, reduce costs and improve productivity by evaluating your existing processes. We also provide quality training to help you master maintenance strategies and become a reliability expert.

No matter your skill level or role, we can help you implement reliability initiatives with confidence. Contact us today to learn more about how we can help you achieve your goals.

MAINTENANCE STRATEGIES OPTIMIZATION

MAINTENANCE STRATEGIES OPTIMIZATION